Greenhouse Case Study

The following application illustrates how C-Fans can enable significant tech opportunities by providing life and reliability in challenging environments, while also enabling new product platforms that solve unique design challenges.

The Industry Problem

In the commercial green house market, certain growers wanted the 40% energy savings and increased crop yields that LED grow lights can provide. But at that time, LED grow lights were not competitive with traditional HPS arc lamps due to the following design challenges (right).

APPLICATION REQUIREMENTS

The grow light footprint needed to be no more than 10in x 20in to minimize blocking of natural sunlight.

When delivering the 90,000 lumen target the 1,500 LEDs created 420W of heat dissipation, which requires forced-air cooling to maintain the rated LED operating temperatures.

Design CHALLENGES

LED life can far outlast fan life in this environment. If properly cooled the LEDs can maintain target lumens for 5 years, but even today’s best rotary fan OEMs offer a 1 year fan warranty.

The fan needs to deliver high air flow rates but must be very quiet, since a typical commercial greenhouse installation will have hundreds of grow lights.

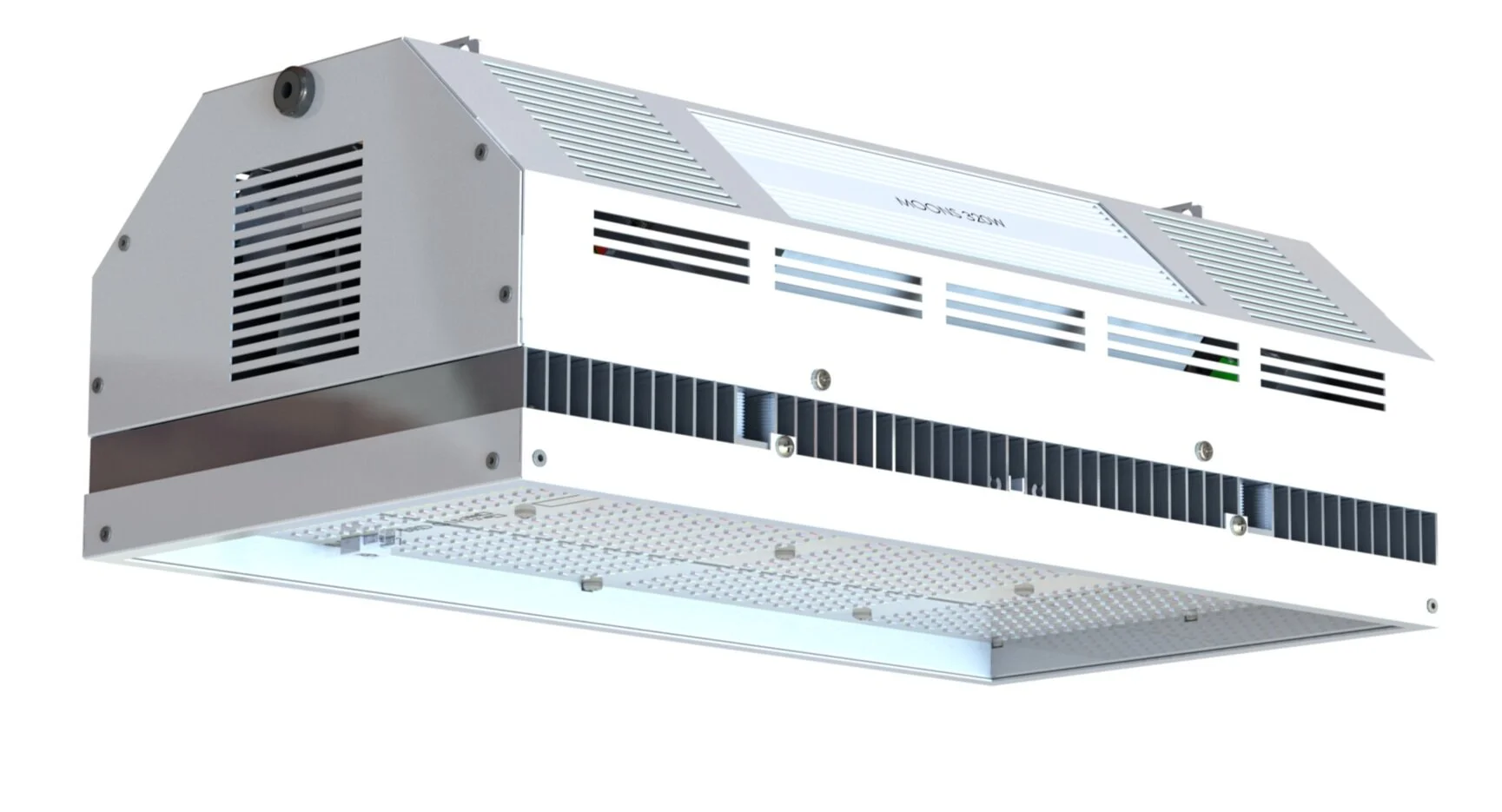

CT141 Customer Installation

The Solution

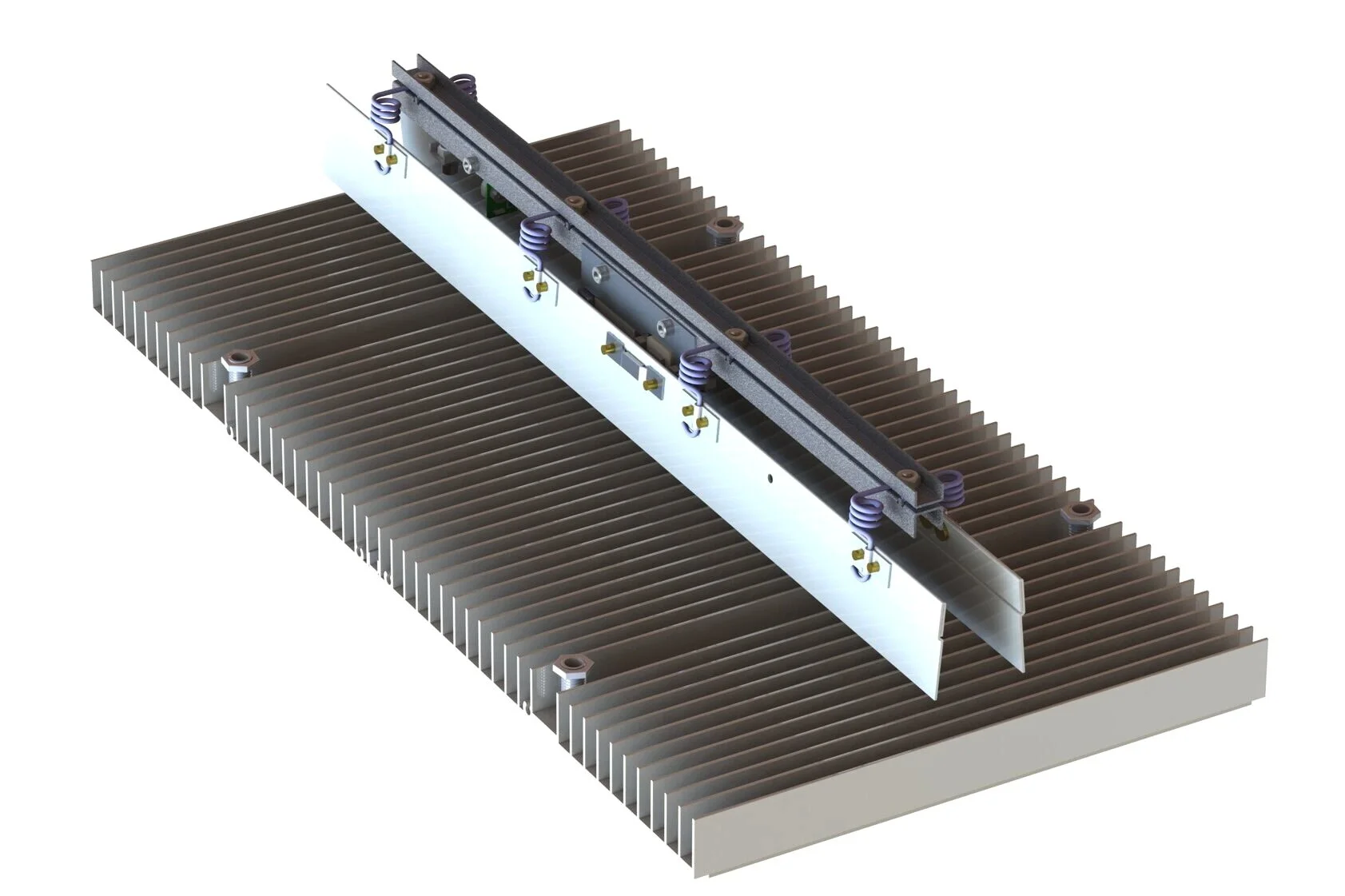

The Product - NeoFan designed the C-Fan and heatsink combination for the customer’s Model CT141 LED grow light that delivers the target 90,000 lumens in a 10in x 20in footprint.

Life and Reliability - C-Fans provide the inherent life required in this application environment and so a 5-year C-Fan warranty was provided to match the 5-year grow light warranty.

FlexFan Adaptive Form-Factors - Unlike rotary fans, C-Fan form factors can be altered in all dimensions to adapt to the product platform requirements. In this case the C-Fan design was stretched along its length.

Maximizing Heat Transfer - A single “stretch” C-Fan provided the higher heat transfer coefficients of impingement air-cooling along the heat sink’s entire 19in width and also delivered air flow with high vorticity at low velocities which further enhances heat transfer. Due to this inherent vorticity, the higher heat transfer coefficients associated with the turbulent regime can be achieved at laminar flow velocities, thereby minimizing the air flow rate needed to achieve the required thermal resistance.

Achieving Low Noise - The delivered air flow is distributed along the 19in long fan blades which minimizes fan exit velocities, enables a low operating frequency of 38Hz and a low resulting fan noise level of 30dBA (at 1m) at a 90CFM flow rate.

Fan-sink performance: 90CFM of impingement air flow, fan power 5W, R = 0.06C/W, ΔT = 25C (die-to-ambient) at 420W of heat dissipation.

Want to Learn More About Our

C-Fan Technology?